Industrial Applications

HD Imaging, IR Imaging and Image Integration

Dage-MTI offers state-of-the art cameras for the stringent demands required in industrial imaging and inspection.

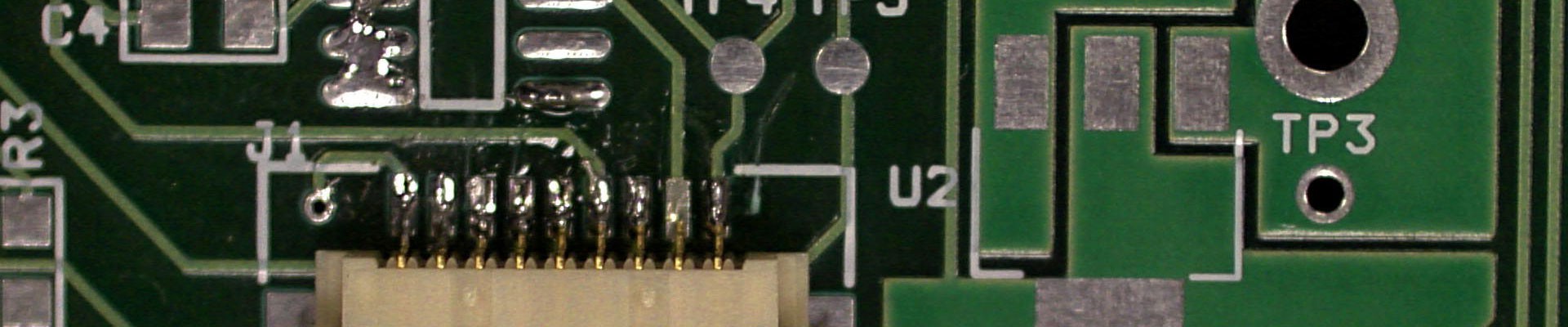

From circuit boards to medical devices; from wafers to forensics to visualizing fluid inclusions in pyrite, Dage-MTI has the tools to help you manage your inspection process needs more efficiently. The small footprint of some of our HD camera heads makes them a “perfect fit” for integration into medical instruments or machine vision systems.

We invite you to look at our HD camera solutions and IR camera solutions for those applications that require the performance of a Dage-MTI product.

Our RV-DR “Magic Box” can provide a HD image capture solution when a computer is not desired as part of the imaging system.

The “InvestiGater” can be a solution in high noise/low signal environments for our near IR camera – the IR-1000. With selectable image integration starting at 2 frames, brilliant images can be produced in difficult imaging situations.

[DAGE_RELATED_PRODUCTS solutions=’industrial-applications’]

Industrial Applications

The InvestiGater enables the acquisition of “noise free” low light level images from the IR-1000 (Spectral response 380nm to 1100nm). The InvestiGater accomplishes this by “gating” (allowing a number of frames to accumulate charge on the CCD detector), grabbing and displaying the image. As long as the signal is present above background noise, the signal from the sample will build up faster than random noise. Unlike Image averaging, the InvestiGater will “normalize” the image to change the range of pixel intensity values to maximize the contrast (histogram or contrast stretching). This can result in brilliant images from low light/low signal environments.

For general parts inspection, we recommend the HD-210U. At 60fps live display, 750 TV lines of resolution and USB 2 connectivity, the HD-210U is a cost effective solution for most brightfield inspection applications. If more resolution is needed and/or the inspection application is somewhat light starved, the HD-336U is a great option. 60fps for both live display and USB 3 connectivity, 1000 TV lines of resolution and fluorescence capable, the HD-336 can handle challenging inspection requirements. We recommend the UHD-4K Ultra HD camera (with 1600 TV lines of resolution) when resolution is most important in a well illuminated, live streaming environment.

The short answer is that specimen details appear closer together at low magnification. To resolve these structures, a higher resolution camera is recommended. If you image a great deal using 2x and 4x objectives, you may want to consider our 3 chip HD-336U or even the ultra HD UHD-4K to resolve structure at these low magnifications.

- Better images on an HD display. The HD camera output is a perfect match to an HD monitor. Your specimens appear as natural as possible with no interpolation or compression artifacts to fit the monitor/projector screen.

- Fast 60 frames/second output.

- Don’t let the camera slow your inspection process!

- Live HD display eliminates eye fatigue from repetitive eyepiece viewing.